Advanced Houston Welding Inspection Techniques for Accurate Results

Advanced Houston Welding Inspection Techniques for Accurate Results

Blog Article

A Comprehensive Overview to Comprehending Exactly How Welding Assessment Works: Methods, Specifications, and Finest Practices for Quality Control in Metal Construction

Recognizing the complexities of welding examination is important for maintaining the stability of metal construction. Implementing finest practices can substantially enhance high quality guarantee procedures. The landscape of welding assessment is not without its difficulties.

Importance of Welding Assessment

Although welding is a critical procedure in numerous markets, its honesty directly affects the security and performance of frameworks and parts. Reliable welding assessment is crucial for determining defects that might endanger the top quality and sturdiness of welded joints. This process guarantees adherence to established specs and standards, which are essential for preserving architectural honesty and operational dependability.

Welding examination serves numerous functions, including confirming that the welding process has been carried out appropriately, examining the high quality of products made use of, and validating that the ended up product fulfills governing and industry standards (Houston Welding Inspection). With rigorous examination, prospective concerns such as porosity, cracks, and incomplete fusion can be discovered early, mitigating and preventing costly repairs safety risks

Moreover, consistent welding inspections foster self-confidence amongst stakeholders, consisting of designers, clients, and regulative bodies, by demonstrating a commitment to quality guarantee. The relevance of welding examination can not be overemphasized; it is important not only for compliance with legal demands yet also for enhancing the general performance of bonded frameworks. Eventually, a robust welding inspection program is an aggressive measure that safeguards against failures, guaranteeing the longevity and dependability of welded elements in their designated applications.

Common Welding Assessment Strategies

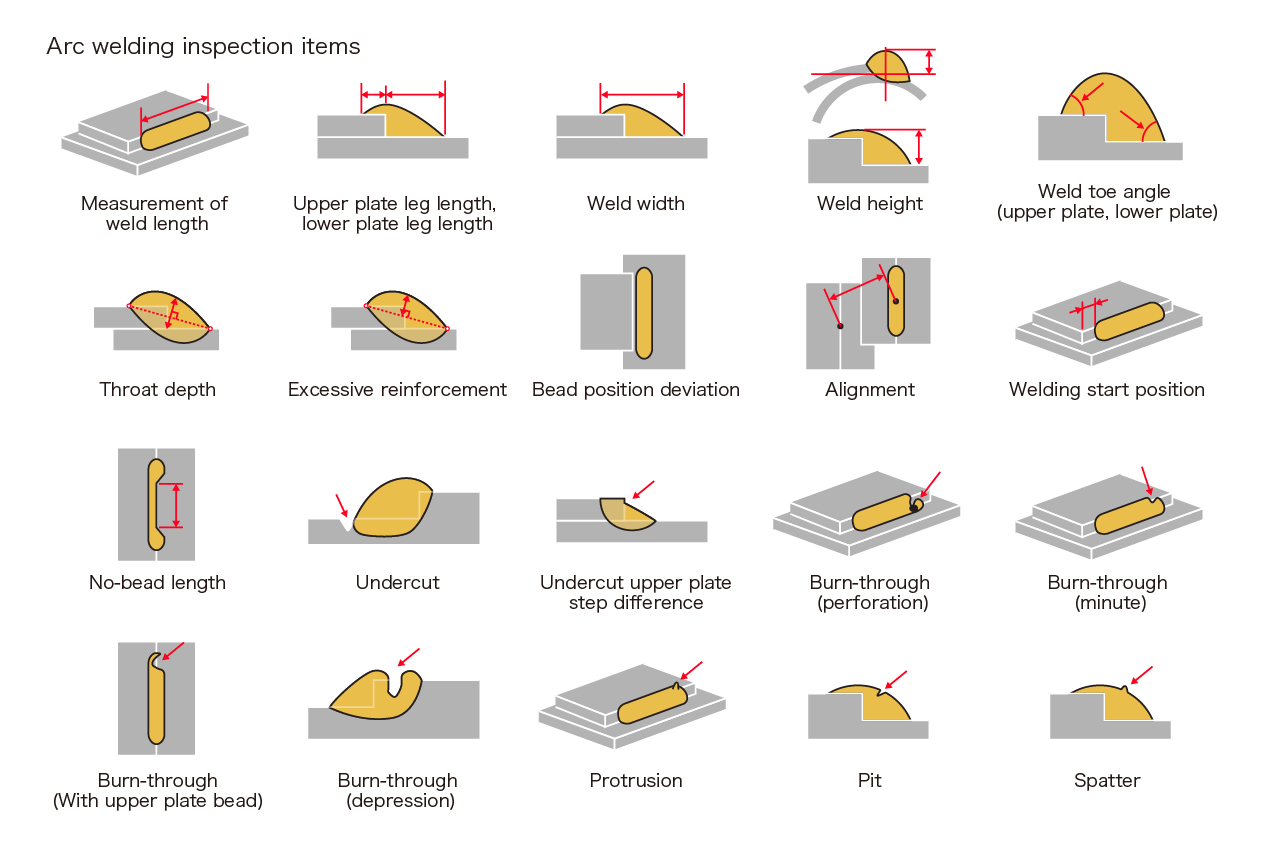

Visual inspection is the initial line of defense, allowing assessors to determine surface flaws such as fractures, undercuts, or insufficient fusion. Radiographic screening uses X-rays or gamma rays to reveal inner defects, making it suitable for complicated welds. Ultrasonic testing uses high-frequency audio waves to spot subsurface problems, offering accurate dimensions of weld integrity.

Magnetic fragment screening works for ferromagnetic materials, highlighting surface and near-surface suspensions when bits are applied to an electromagnetic field. Conversely, color penetrant testing utilizes a fluid dye to disclose surface-breaking problems, making certain that even the tiniest defects are spotted.

Each strategy has its toughness and restrictions, usually requiring a mix of methods for detailed analysis - Houston Welding Inspection. By applying these evaluation techniques, quality control in steel construction is attained, ensuring that welded frameworks meet security and efficiency criteria

Industry Specifications for Welding

The American Welding Society (AWS) and the American National Criteria Institute (ANSI) are two famous companies that develop welding criteria. AWS D1.1, for instance, lays out the needs for welding steel frameworks, while AWS D1.2 concentrates on light weight aluminum. Internationally, the ISO 3834 standard addresses quality requirements for fusion welding, offering a framework appropriate across national borders.

Ideal Practices for Top Quality Assurance

Quality assurance in welding is paramount to attaining safe and sturdy building and constructions. Carrying out best techniques makes sure that every weld satisfies the required specs and standards. Establishing a detailed top quality management system (QMS) tailored to the particular welding project is essential. This QMS must specify treatments, roles, and obligations to reduce threats and enhance liability.

Routine training and qualification of welding personnel are important for keeping a skilled workforce. Constant education and learning on the newest welding methods and modern technologies ensures that inspectors and welders are experienced concerning existing standards and methods.

Additionally, performing pre-weld examinations to evaluate products and devices can protect against flaws before they happen. Houston Welding Inspection. During the welding procedure, real-time surveillance and documentation of welding parameters help identify inconsistencies immediately. Post-weld inspections must entail extensive examinations see here using non-destructive testing (NDT) approaches to make sure the honesty of the welds

In addition, preserving clear interaction amongst staff member advertises a culture of high quality. Routine audits and testimonials of the welding process assistance identify locations for renovation. By adhering to these ideal methods, companies can achieve ideal high quality guarantee, eventually resulting in improved safety and performance in steel manufacture tasks.

Difficulties in Welding Evaluation

Although welding evaluation is crucial for guaranteeing structural honesty, it provides a range of challenges that can make complex the analysis process. One significant obstacle is the variability in welding techniques and products utilized, which can affect the uniformity of weld high quality. Different welders may use varying methods, bring about disparities that inspectors need to review and determine.

One more challenge entails the detection of issues. Non-destructive testing (NDT) approaches, such as ultrasonic and radiographic screening, can be intricate and call for competent professionals to translate outcomes accurately. Incorrect positives or downsides can happen, potentially causing expensive rework or compromised safety and security.

Furthermore, the presence of ecological elements, such as temperature and moisture, can influence the honesty of welds and the effectiveness of examination techniques. Assessors must additionally navigate the governing landscape, guaranteeing conformity with industry criteria, which can vary by territory and application.

Conclusion

To conclude, welding evaluation plays an essential function in making certain the integrity and safety and security of metal construction. Using a range of examination techniques, sticking to established market criteria, and implementing efficient top quality management methods jointly enhance the reliability of bonded frameworks. Despite the difficulties dealt with in the examination process, a commitment to constant renovation and adherence to best practices can substantially strengthen the quality control framework, promoting better self-confidence among stakeholders in the welding industry.

Efficient welding assessment is crucial for identifying defects that could jeopardize the high quality and longevity of bonded joints.Moreover, consistent welding evaluations foster confidence among stakeholders, including engineers, clients, and regulatory bodies, by demonstrating a commitment to high quality assurance.The American Welding Society (AWS) and the American National Specification Institute (ANSI) are two prominent companies that establish welding standards. During the welding procedure, real-time surveillance and documents of welding parameters aid identify incongruities immediately. Despite the challenges encountered view in the examination procedure, a dedication to constant improvement and adherence to best techniques can dramatically strengthen the high quality assurance framework, cultivating home better confidence among stakeholders in the welding sector.

Report this page